Pure Prime Solutions (PPS) is a team of experts with deep knowledge in engineering design, simulation, analysis, and testing. We are committed to providing our clients with the best service possible by augmenting their technical capabilities. We've helped many companies realize their goals.

The Value You Demand: Successful businesses demand proactive problem solving, reduced learning curve, successful methodologies, and a diminished risk of budget and schedule creep. PPS's 40-year-collective technical expertise delivers on this requirement.

Nick Duff & Tom Cushing, President & Vice President, comprise our core team to serve you…

MEng | President & Co-Founder

Nick Duff is a military veteran, holds an advanced engineering degree, and has significant industry experience. Nick is a veteran of the United States Marine Corps (USMC). After serving, Nick earned both Bachelor's and Master's degrees in Mechanical Engineering from the University of Louisville J.B. Speed School of Engineering. As a lifelong learner, Nick has dedicated his life to helping others by designing cost-effective solutions to solve complex and expensive problems. With years of mechanical design and engineering experience, Nick has developed expertise in several areas, including:

MEng, MBA | Vice President & Co-founder

Tom Cushing is a military veteran, holds advanced engineering and MBA degrees, and has considerable industry experience. Tom is a veteran of the United States Army, having served one tour supporting Operation Iraqi Freedom. After serving, Tom earned both Bachelor's and Master's degrees in Mechanical Engineering from the University of Louisville J.B. Speed School of Engineering and a Master of Business Administration (MBA) degree. As an entrepreneur, Tom is giving back to society by designing cost-effective solutions to solve complex and expensive problems—to improve life quality. With years of mechanical engineering experience, Tom has developed expertise in several areas, including:

Nick and Tom met in college and found that they shared some similarities. Both joined the military after high school, just different branches of the military. Upon return from service, they both worked jobs and studying - at the same university to obtain undergrad and graduate degrees in mechanical engineering (Tom also earned an MBA). After each had gained essential experience in various industries, they decided to form an engineering services organization to provide design, simulation, analysis, & testing… PPS was born—to serve you.

Engineering is creating systems, products, and projects that conserve resources by considering cost-competitiveness to generate quality in the shortest time possible.

PPS helps companies design environmentally-friendly equipment using simulation, which is faster and more accurate than traditional trial-and-error methods. Companies have expertise in their industry that few can tap into due to lack of resources or access to an expert. PPS works with them as a consultant during the entire process from start to finish, so they end up with green systems without having had any previous experience building one themselves."

Tactical execution requires skills and knowledge in crucial areas: engineering physics, analysis methodologies, computer-aided design (CAD) software, computer-aided engineering (CAE) software, and Tribal Knowledge.

Most companies follow a traditional design, build, and test process that is costly and time-consuming—leading to risk avoidance (e.g., we've always done it this way.").

The design works, but is it the best, most efficient, and achievable within budget and time constraints?

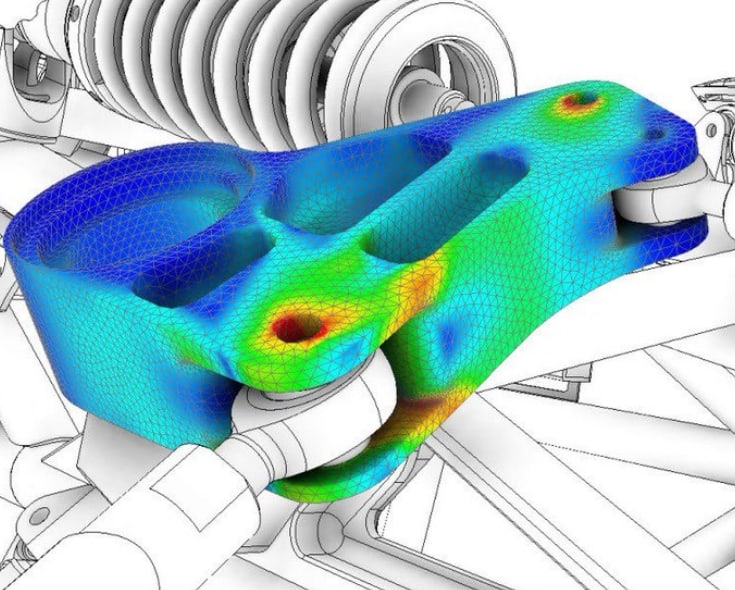

Our simulation-driven approach optimizes and validates design performance across multiple disciplines encompassing structures, motion, fluids, and thermal management modeling, providing data analytics and true-to-life performance.

Before we spend resources on a single design, we need to know the following about the design:

Testing design theories with a virtual prototype reduces physical prototyping time and cost, allowing multiple design iterations to be evaluated in parallel, leading to more efficient designs.

PPS simulation-driven approach is designed to be performed during the conceptual phase of the design process. Because moving engineering and analysis to the conceptual stage of development has several effects:

Before we spend resources on a single design, we need to know the following about the design:

Customers and new challenges and demands often lead to custom parts or unique products tailored to clients' needs in today's ever-changing world. Then there is the emergence of new manufacturing and construction techniques like computer-driven machinery (CNC), mass customization where each run is different. Additive manufacturing and 3D Printing. Additionally, the manufacturer's ability to design a product for manufacturing and assembly, especially in products, is intense. The ability to create a product that takes less material and needs fewer person-hours to assemble is paramount in today's cost-competitive marketplace. All of this has led to an increased emphasis on simulation! To compete today's companies, need to be able to:

A decision-making process is a key to improved decision-making. Have the ability to generate more data and know what the data means? Knowing what to do with the information is the key!To compete today's companies, need to be able to:

Our simulation-driven approach optimizes and validates design performance across multiple disciplines encompassing structures, motion, fluids, and thermal management modeling—providing data analytics and true-to-life performance. You benefit from reduced development times and lower costs throughout the product life cycle—conceptual design through in-service operation.

The overall impact of a simulation-driven design process is a 14% reduction in time to market.

There are several paths to make you successful with varying degrees of commitment:

We work with organizations that want occasional or ongoing engineering support or mentoring…

"Augmenting your technical capabilities—at the ready, to serve you with Design, Simulation, Analysis, & Testing."

PPS qualifies as a Service Disabled Veteran Owned Small Business (SDVOSB). But, what does that mean to you?

"When the job's not easy, you need the best people you can get." —PPS. Military Commitment - Academic Credentials - Industry Experience

Pure Prime Solutions is a company with vast engineering design, simulation, analysis, and testing capabilities. This team of experts can help you with engineering support and mentoring. PPS is an SDVOSB (Service Disabled Veteran Owned Small Business), which means you can get military commitment and preferential status when bidding on government contracts. PPS is committed to completing the tasks that they take on. PPS is a great company to work with.

Augmenting your technical capabilities—at the ready, to serve you with Design, Simulation, Analysis, & Testing.

Contact Us to learn more.