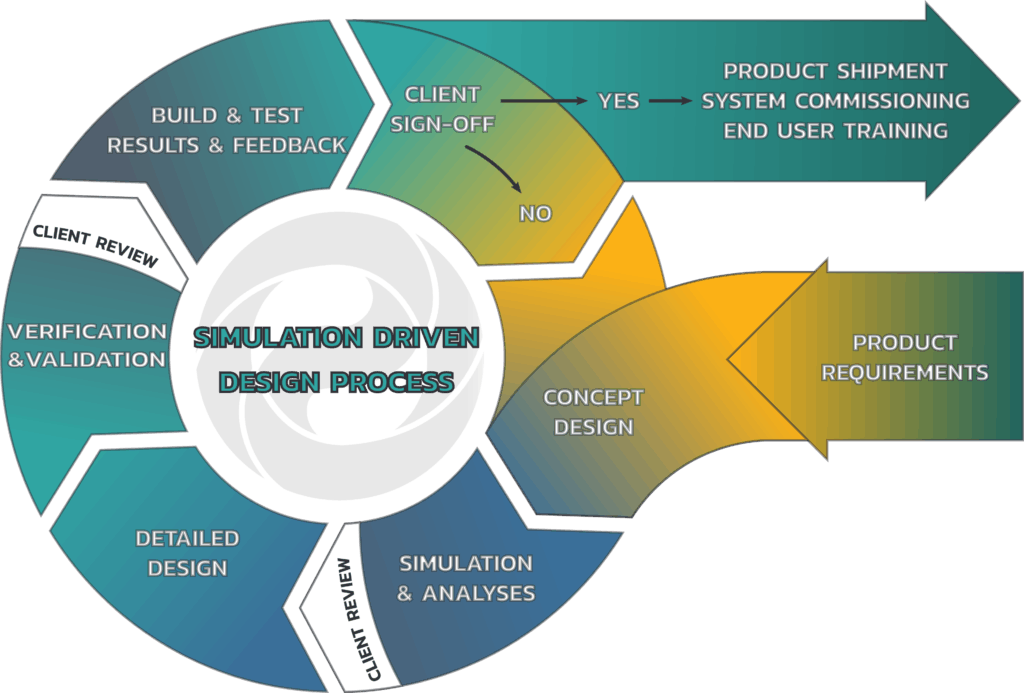

- Defining The Project Requirements (Scope)

- Concept Development And Evaluation

- FMEA - Failure Mode And Effects Analysis And FTA - Fault Tree Analysis

- Simulation And Analysis ( Engineering With A Client Review)

- CFD - Computational Fluid Dynamics And FEA - Finite Element Analysis

- 3D Modeling, Detail Design, And Documentation Production

- DFMA - Design For Manufacture And Assembly

- Design Verification And Validation ( Client Review)

- CFD - Computational Fluid Dynamics And FEA - Finite Element Analysis

- Product Production ( Manufacturing & Testing)

- Client Review And Final Acceptance

- Installation, Equipment Commissioning, And Training