Automated Engineering Services: Connect and Collaborate

The Old Way of Designing Products And Bringing Them To Market Is Obsolete.

PPS’s engineering and design experience provides technical services

PPS understands design and cost constraints.

The PPS partnership approach is to function as an extension of your team.

PPS’s team has decades of engineering and design experience partnering

In the cement industry, reliability is the product of maintenance and equipment design. However, many factors limit the degree of reliability that maintenance teams deliver. It is critical that the equipment be designed to adequately perform its required function.

Cement manufacturers have expertise in their industry, natural raw materials, processes, and in-services equipment to produce cement to fill the needs of ready mix concrete which is one of the key building materials to support our nation's growth.

How does operations actually use the equipment? This is a good question if you want to solve issues and not fight fires. Generally, every plant operates a little differently. However, Original Equipment Manufacturers (OEMs) designed the equipment using a specification supplied from or agreed to from the plant owner—often without taking into account how the equipment will actually be operated during production.

We founded Pure Prime Solutions (PPS) to partner with companies to develop environmentally sustainable processes and equipment through a simulation-driven approach. Note: There is nothing sustainable when you're fighting fires environmentally or otherwise.

How does operations actually use the equipment? This is a good question if you want to solve issues and not fight fires. Generally, every plant operates a little differently.

We founded Pure Prime Solutions (PPS) to partner with companies to develop environmentally sustainable processes and equipment through a simulation-driven approach.

Nick Duff & Tom Cushing (President & VP, respectively) are both disciplined military veterans, have MEng Degrees in Mechanical Engineering (Tom also has an MBA), and each has significant cement industry experience. They teamed up to provide cost-effective solutions through data-driven simulation and analysis.

The Value You Demand: Successful businesses demand proactive problem solving, reduced learning curve, successful methodologies, and a diminished risk of budget and schedule creep. PPS's 40-year-collective technical expertise delivers on this requirement.

"Augmenting your technical capabilities —at the ready, to serve you with Design, Simulation, Analysis, & Testing."

Learn more about "Who We Are" on the ABOUT US page.

Simulation Analysis is the process of developing a mathematical representation of an actual or proposed product to make sure that it will work as intended. Simulation can also be used for predictive maintenance by testing durability and reliability in the cloud. Engineers who use simulation analysis can verify their products much more quickly than doing hand calculations, which could take years instead of minutes!

PPS can simulate cement dust distribution in airflow, and using simulation analyses to verify product performance over its lifetime to predict when it will need maintenance (i.e., predictive maintenance).

We package a wide range of equipment options. We are not limited. We develop cost-effective environmental solutions—including green cement—that exceed your reliability requirement while meeting the needs of ready mix concrete—one of the essential building materials required for new construction projects. Simulation is fast while being precise to predict breakdowns accurately. We work with cement plant maintenance professionals to overcome barriers to achieving reliability in the manufacture of portland cement.

The Old Way of Designing Products And Bringing Them To Market Is Obsolete.

Go Slow to Go Fast: The fastest way to succeed and win.

Pure Prime Solutions delivers integrated engineering design, development, and sustainability solutions that harness digital strategies to reduce costs, improve performance, and increase productivity

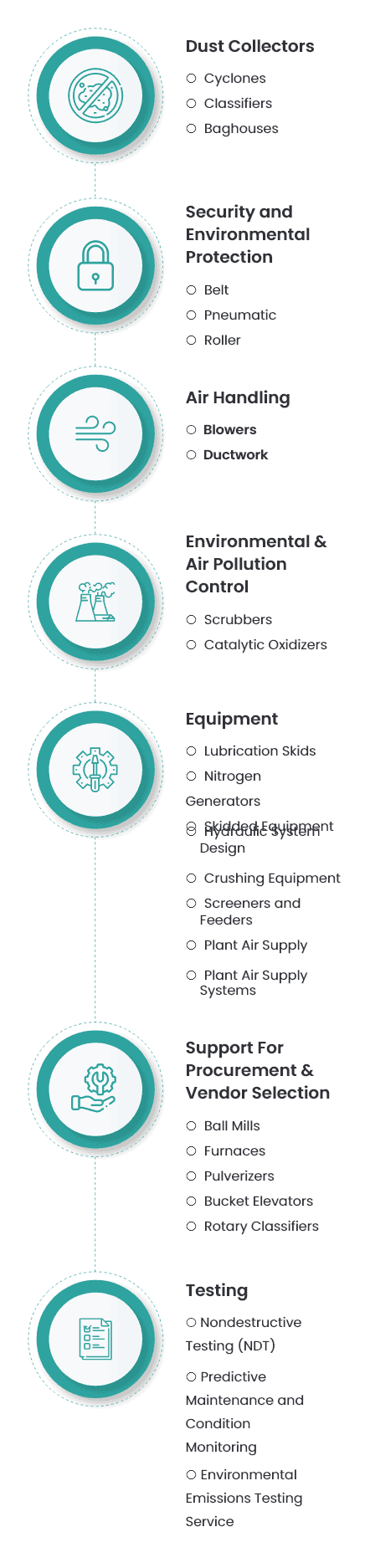

With our Cement Manufacturing Services we not only design, engineer, and manufacture, but we also support all of the equipment needed to manufacture cement. We are cement-plant-equipment-design experts. Instead of spending millions on tribal-knowledge-based equipment redesign, let our cement equipment design engineers design the cement plant dust collection system that will meet your operating requirements and achieve Cement Waste Minimization (CWM) using advanced technology and data-driven simulation analyses for the cement industry.

It is crucial to utilize the right equipment. Our cement plant design engineers will simulate and analyze your dust collection system to ensure that you have the most reliable dust collection system possible. We know how to deal with tricky situations as you produce cement—like high dust loads, material grades, moisture content, etc., and guarantee maximum reliability at an affordable cost.

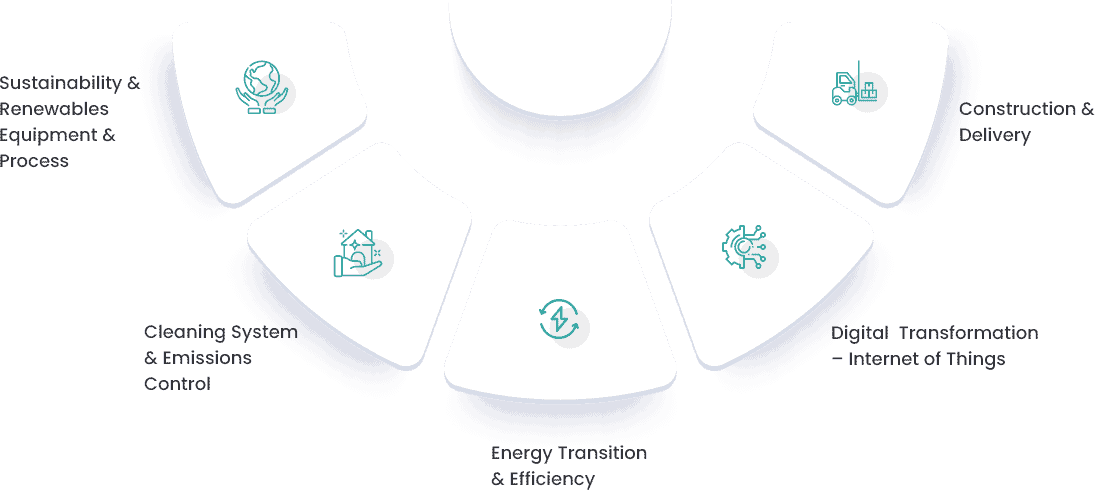

Pure Prime Solutions is an American based service company providing Cement Plant Maintenance Professionals with quality equipment and services. Cement industry professionals can consider us on projects related to any of these five areas:

At Pure Prime Solutions, our core focus is providing the best equipment maintenance and solutions to various industries. Our company was founded on decades of experience with equipment design, simulation, and analysis of industrial assets. This experience allows us to develop many innovative approaches that solve reliability problems.

Our team has the expertise need to design and construct new processing plants and optimizing existing plants for better performance, understanding operational needs and delivering better equipment through simulation-driven approaches.

The surest way to align a cement plant with the environment is by having a detailed understanding of its equipment design, operational performance, and real-world environmental impacts—including the increasing demand for green cement as one of the sought after construction materials. Our process starts with understanding what problems cement manufacturers are facing. We then apply specialized expertise to deliver the solutions that align with stakeholders' challenges and goals.. We ensure all project objectives are met within strict time frames by working closely with our cement manufacturers' people and teams. On the one hand, industrial assets such as dust collectors provide a crucial role in maintaining machinery function and efficiency. On the other hand, industrial assets create an environmental burden on communities and ecosystems.

Helping professionals at cement plants improve their current manufacturing process equipment performance through environmentally sustainable processes through better designs, operations solutions, simulation-driven analysis, process improvement, asset management, and equipment modification for better operation, reliability—to support construction services, communities, and the environment.

.

.

.

.

.

.

The Cement Industry Services and Solutions of Pure Prime Solutions provides Cement Plant Maintenance Professionals with resources to level up equipment reliability performance. This is done through an environmentally sustainable process design approach that starts with defining the root cause and ends in a complete understanding of equipment design, operational performance, and real-world environmental impacts.

PPS Cement Industry Services has made possible simulation-driven analysis, process-improvement collaborations, process asset management, and better process equipment designs for communities and environments.

Cement Plant Maintenance Professionals that partner with PPS Cement Industry Services can maintain equipment reliability and performance while reducing environmental burdens and improving Cement Plant Operations.