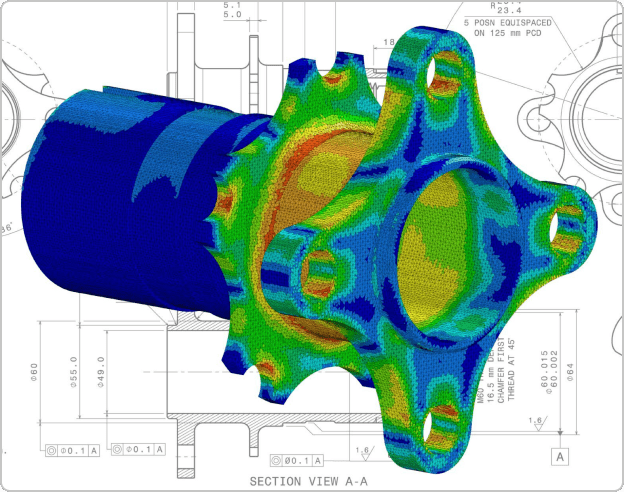

FEA uses engineering simulation software to create a mathematical model during the design process. We can create a possible solution to how a physical system will behave in the real world with FEA.

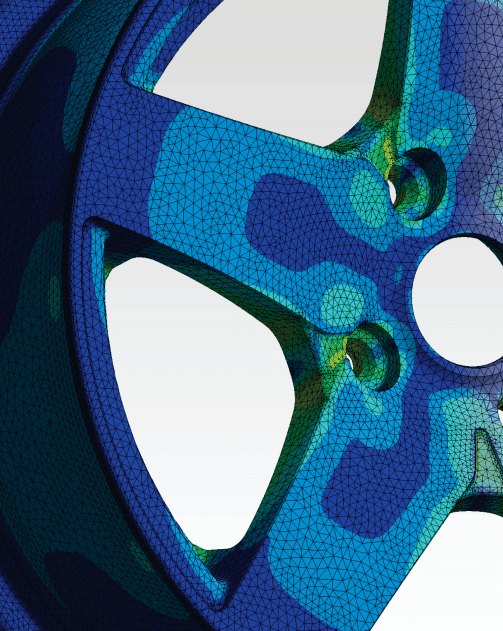

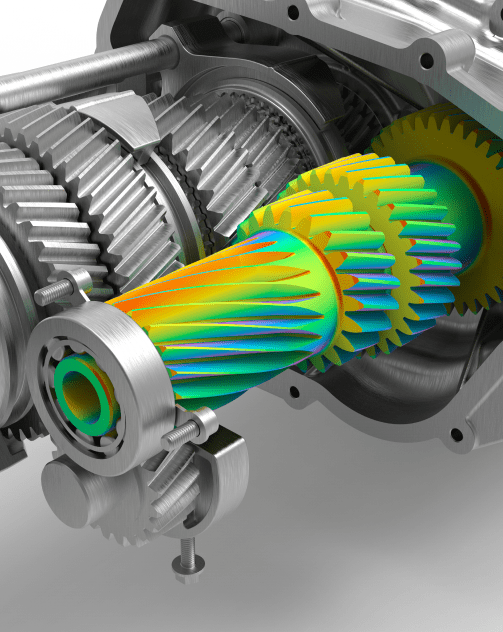

One benefit of FEA is creating a design to look at its structure. We do this by using stress and strain curves, boundary conditions, and equipment components. The simulation shows you specific conditions your design will face in the real world, resulting in:

You can see how a design works by trial and error, but that means repeating the design-build process until you find a design that works. That is a slow process and takes too much time, plus it costs a fortune.

FEA uses virtual prototype modeling to predict how a design will behave and cut the high cost of making physical prototypes and repeatedly testing. The result minimizes design, development, quality, and manufacturing risks. You can keep designing quickly to find the right design before you build anything.

FEA makes it possible to simulate complex boundary conditions. FEA provides accurate results in a short time, at a lower cost. But is finite element analysis difficult?

It can be because you need in-depth knowledge of the FEA. Engineers using FEA must understand how to study a complex structure and its physical elements to simulate structural conditions to find the right design.