Once upon a time, when a business offered customized products, it would have an engineering team on staff. We can now connect and automate the design process across software platforms and companies.

Custom products are often ‘the same but different,’ sharing a standard design that can be customized to meet the customer’s needs. Engineers usually copy 3D CAD models and adjust the product’s dimensions, visibility, and parts to meet the customer’s requirements. The engineering process is slow and error-prone and not cheap either!

Advanced design methods and collaborative product development (PDM) are better product design methods. These technologies allow real-time collaboration between engineering teams, their clients, and their customers. Instead of manually updating 3D models with customer requests, engineers can automate those processes. Design automation tools such as DriveWorks and Autodesk Platform Services (Autodesk Forge) can be used for this purpose.

How Does Design Automation Work?

Engineers use design automation tools to conquer the challenge of creating custom-made products. These tools allow for efficiently reusing the knowledge gained from previous projects without manually recreating documents and data.

This reduces the time and cost associated with designing and manufacturing custom products, making them more cost effective. Additionally, these tools help ensure that the design, process, manufacturing, and cost estimates conform to the required standards. Ensuring they are all accurate and up to date.

Typically, CAD software outputs in multiple formats for different purposes. You might need additional files for certification or production and different versions of those files for different locales. Then, if you want to change the design later, you must start again with a new set of files.

That’s where digital technologies like design automation come in. Industry 4.0 design automation tools allow us to store knowledge from design and production. This knowledge can then be used to make and market custom products.

We’re not quite there yet. We’re building an automated engineering services platform to help you connect with our engineers and streamline every process step. I mean every process step from concept to end-of-life life to capture, document, and generation designers.

Capturing Engineering Knowledge

When you’re an OEM, it’s essential that you have the right digital lifecycle management tools for the job. Regarding product development, that means accessing advanced design methods. Additionally, industry 4.0 technologies and software can help automate product development.

But there’s a catch: Design engineers are often experts in their field and have years of experience designing products. So how do you leverage that knowledge without losing it?

One solution is to use rules to capture the knowledge and actions of these engineers. These rules include equations, sums, business logic, legislation even product requirements! They can be simple actions or complex calculations.

They can even use information from databases, web services, and integrations with other company systems! Digital transformation is essential for companies to quickly redesign their products with fewer errors, increased efficiency, and cost savings.

Benefits of Design Automation

Design Automation: A Way to Solve the Demand for Skilled People

The world changes faster than ever. We’re closer than ever to a sustainable future, but we must continue innovating and finding new ways to improve ourselves. That’s why design automation is so important.

Design automation is an excellent way for companies across all industries to save time, reduce errors, and increase productivity. We live in a world where the demand for skilled engineers is snowballing. Yet too many positions still need to be filled due to a lack of supply.

With the help of design automation tools, we can design, analyze, and manage products more efficiently than ever. Design automation is a powerful tool that enables our team’s knowledge, analysis, and experience to be captured and reused. Design automation is more efficient and precise than manual design work. When the system is established and tested, the results will be consistent.

Engineering teams can be liberated from tedious, time consuming duties to prioritize higher output and custom design issues. It allows engineering teams to perform design and analysis to upgrade existing or new products and develop sustainable products. This automated process saves you time, reducing errors and increasing productivity. It is a business model that delivers sustainable development and lower total cost.

Integration with other company systems

Imagine getting the design right the first time, every time. Imagine if your design could automatically update information in other systems, so you didn’t have to worry about manual data entry. Imagine if you could use outsourced engineering services (OES), and pay as you go, resulting in a lower cost. We can help make that dream a reality.

Custom product configuration, document preparation, and the big data needed for sales and manufacturing often require data to be shared. This data needs to be updated regularly. Automating the product development process with cloud computing speeds up and reduces the risk of manual data entry mistakes.

Using data from an ERP system, one can obtain precise details about manufacturing dates to ensure sales have correct lead times. You could use information from your product lifecycle management (PLM) to find a substitute part.

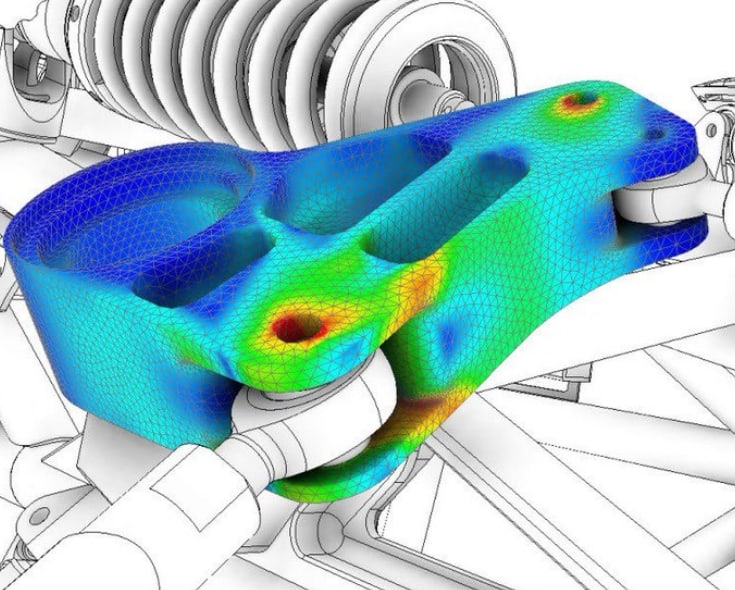

Then, you could update computer aided design (CAD) and run an analysis using computer aided engineering (CAE) or other CAE tools.

Cloud computing enables us to run any application on demand, anywhere we want—and it’s cheaper than ever. We understand the great significance of the fourth industrial revolution. For businesses like yours to stay ahead of the competition in this modern era.

Design Automation Services Building an online user portal.

You need a dependable partner to assist you with product design, from user experience to complex digital design. That’s where Pure Prime Solutions comes in. We offer engineering services, including product lifecycle management, CAE software, engineering applications, and digital transformation. Our products and services help Original Equipment Manufacturers (OEMs) reduce time and cost and improve collaboration with suppliers and partners.

The long term outcome is to ensure you get the product you need when you need it. That’s why we’re making accessing the latest advanced design methods and digital technologies easier. We’re ensuring you can get the information you need, no matter where you are or your device.

Final Thoughts

Ultimately, we’re bringing the latest technologies to bear and working with our clients to create better products. We’re helping manufacturers improve efficiency, speed their time to market, and reduce costs. This is achieved by reducing manual labor hours and requiring physical prototypes. Design automation is a critical step for today’s smart factories and soon.

We can help you succeed in today’s manufacturing environment regardless of your industry or company size.