Introduction

The economy is shifting toward an innovative mindset that embraces new technologies. Although the construction industry has been slow to adopt new solutions, it is starting to catch up. Modern buildings need flexibility in design and operation while focusing on sustainability.

Developers have been exploring ways to save energy, reduce CO2 emissions and save operation costs. Computational fluid dynamics (CFD) modeling allows engineers to design more efficient, cost effective HVAC systems.

Today’s blog will discuss CFD in construction and how it impacts HVAC systems.

Ventilation and Thermal Comfort

CFD reduces energy consumption by optimizing the thermal comfort and ventilation of buildings. The process begins by modeling a building’s geometry, environmental conditions, and occupant behavior. Data produced from CFD simulation leads to better design decisions, leading to higher energy efficiency and lower HVAC costs.

Sustainable Design of Complex Heating, Ventilation, and Air Conditioning (HVAC) System

CFD lets engineers improve HVAC systems in various ways, such as making them more effective at heat exchange, reducing operating costs, lengthening equipment life, and improving indoor air quality.

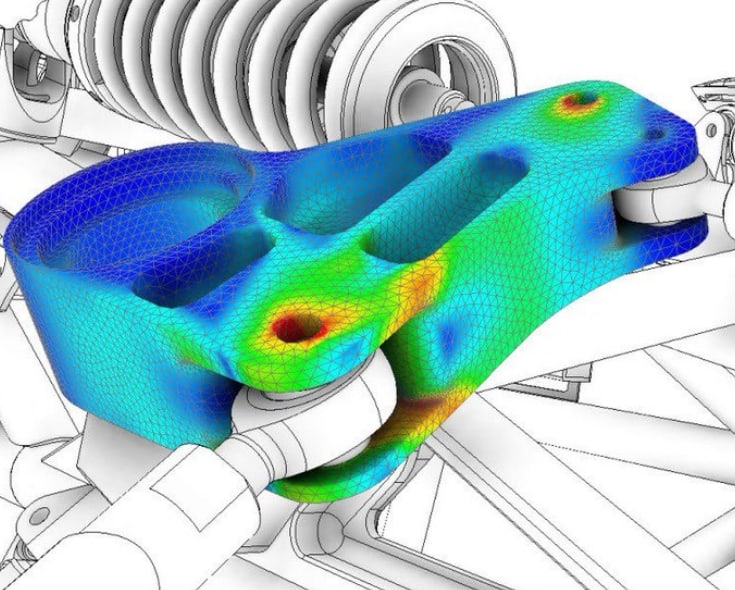

CFD can help engineers predict how a system will perform in terms of heat transfer, fluid flow, and pressure, allowing them to test how it will operate under different conditions. For example, how best to use passive and mechanical means to maintain a comfortable indoor environment.

The design of an HVAC system is constrained by the laws of thermodynamics, fluid mechanics, and heat transfer. When designing HVAC systems, engineers must take into account many interacting variables. These variables included the geometry of the ductwork, air-side conditions like the temperature or humidity, equipment capacity, and performance characteristics.

The goal of CFD in HVAC is to minimize the energy consumption of buildings while providing thermal comfort to occupants. The benefits of using CFD to optimize HVAC Systems are as follows:

- Temperature & humidity profiles throughout the building can enhance current designs or create new ones that better suit the occupants’ needs.

- Determine airflow patterns and velocities to improve ductwork designs and select more efficient HVAC equipment.

- Identifying areas in a space that are underserved by the HVAC system leads to design changes in system design for improvement.

- Optimize damper positions for zone control systems to minimize energy consumption while providing thermal comfort.

- Improved understanding of how changes in set points (heating, cooling, demand ventilation, etc.) will impact energy use and thermal comfort levels throughout a space.

Efficient HVAC systems begin with understanding the occupants’ needs and how they interact with the space. CFD simulations can determine the proper system settings during a project’s design phase when it is the most cost effective. Resulting in achieving sustainability goals and occupant comfortability needs – faster and cheaper.

External Building Aerodynamics

The construction industry is undergoing a major transformation. Developers want to build complex buildings that need greater structure and design complexity. This design complexity is because surrounding environments continue to grow. CFD simulation provides decision makers with cost effective and insightful data to understand external aerodynamics.

When wind hits buildings or structures, it can be difficult to predict how it will behave. How does the neighboring building affect wind velocity and pressure on the building? What if the area experienced extreme weather like hurricanes and tornadoes? How well will the building withstand these extreme events?

Developers use CFD to analyze airflow patterns around complex structures. Using this information, they can optimize designs before setting them into production. This allows them to save valuable time and money while ensuring better results at the end of the day.

CFD also has many other benefits. For example, it can identify design problems and improve buildings’ safety before they become an issue.

For instance, simulations of External Building Aerodynamics reveal how the space between two building parts can cause turbulence and low-pressure areas, leading to structural damage over time.

HVAC System & Equipment Design

Product design of heating, ventilation and air conditioning (HVAC) is a mature industry that has been around for a century. Yet, there’s increasing pressure to differentiate products by increasing efficiency while reducing costs. CFD allows engineers to meet performance and cost goals. To meet these goals, engineers create virtual prototypes that simulate air handler equipment performance.

Manufacturers can avoid building costly physical prototypes during their preliminary design. This allows them to identify design problems as early as possible to optimize the design and operation of HVAC equipment. HVAC engineers work with many design constraints, including limited budgets and tight deadlines. CFD simulations are helping engineers to optimize and confirm HVAC system designs, saving them a lot of time and effort.

HVAC engineers use CFD to study how different design scenarios affect heat transfer and airflow through a building. When designing the HVAC system for an office building, engineers need to know each room’s heat and air conditioning requirements. This will assure comfortable conditions year-round.

Fire and Smoke Propagation

The CFD tool has revolutionized HVAC design by enabling designers to visualize and test their systems in action. Now, engineers are using it in fire and smoke management applications. Using the tool to imagine concepts that have yet to be built.

New buildings have fire and smoke management systems regulations that protect buildings and their occupants from fire and smoke. Delivering longer structural integrity during a fire saves lives and reduces rebuilding costs.

CFD simulation data gives engineers an understanding of how fires spread through the building. This resulted in learning what effects different ventilation scenarios have and where to place safe egress.

In some cases, CFD has even been used to diagnose problems with existing buildings that have experienced fires. To simulate the spread of fire and smoke in a building, CFD engineers must ensure that they have the proper boundary conditions. For example, fire temperature, air velocity, and fuel species boundary conditions must be specified.

If the ventilation system is being modeled, inputs on air flow rates are required. In addition to specifying these boundary conditions, it is also necessary to specify any ventilation system inputs (for example, airflow rates). This ensures that smoke is dispersed throughout the building in a realistic manner.

The CFD simulation model must also be validated against experimental data from an actual fire. This requires understanding how fire spreads through different materials (e.g., wood, plastic, drywall, etc.) at different temperatures and pressures. You can compare experimental data with results from a CFD model to see if the model needs to be adjusted or if more simulations need to be run.

Why do we just physically test fire scenarios with smoke bombs after the building has been built?

Physical tests of fire scenarios are expensive and labor intensive. Moreover, testing after the building has been built leads to major drawbacks:

- Engineers will rely upon what has always worked in the past to achieve a successful testing outcome? This type of mindset results in less innovative and more expensive HVAC designs.

- What happens if the design fails a physical test? Changing the design after construction is very difficult, leading to cost overruns and project delays.

- Engineers cannot optimize and validate HVAC system design during the planning and design stage of a project.

Engineers are turning to CFD simulations to optimize and confirm HVAC system design, saving them a great deal of time and effort. A validated CFD model can recognize how fires start, progress, and affect the building.

We perform systematic studies to understand how building design is affected by fire and smoke propagation and consider likely fire scenarios. This leads to developing a fire mitigation system optimized for emergency evacuation procedures.

Conclusion

These are some of the most common applications, but there is much more to come. CFD is integral to the design and development process throughout many industries. The HVAC industry strives to build better buildings and products.

They must use engineering technology like CFD in their R&D efforts to do so. Leading to more efficient air conditioner systems and air handling units that are more sustainable. CFD Simulation encourages collaboration and the sharing of ideas across engineering specialties. The expanded use of CFD technology results in more innovative solutions.

One Response

Fascinating read! Your article on the evolving boundaries of HVAC design is both insightful and forward-thinking. It’s exciting to see how advancements in technology and changing environmental standards are driving innovation in the HVAC industry.

The discussion on integrating smart technologies and sustainable practices into HVAC design is particularly compelling. The shift towards energy efficiency and eco-friendly solutions not only benefits the environment but also offers significant cost savings for consumers. Your examples of how these changes are being implemented in real-world applications provide a clear picture of the future of HVAC.

For future articles, it would be great to dive deeper into specific case studies of innovative HVAC designs and their impact on both residential and commercial buildings. Additionally, exploring the role of AI and machine learning in predictive maintenance and system optimization could provide even more insights into the future of HVAC technology.

Thank you for shedding light on these important trends. Your article is a valuable resource for anyone interested in the future of HVAC design and its potential to transform our living and working environments.