In Chapter 1, we outlined an understanding of what the answers mean! Or, more precisely, How to determine what the answers mean through understating what an allowable. In this chapter, we will begin discussing Static Theories of Failure and why they’re important. Below we cover the beginning to uncover some best practices. For more of a textbook review, we recommend reviewing this PDF from Michigan State University.

Static Theories of Failure- How to Select the Right One

Static Theories of Failure are material, load, and environment-dependent, and I cannot emphasize that enough. If you do not understand what type of material you are working with, how the load is applied, and the environment the material lives in, You CAN NOT perform a thorough analysis. It is impossible; do not even try it.

Ductile vs. Brittle Material

Many different types of material are not just ductile or brittle. One example is a composite material like a prepreg composite layup that can have the properties of both. For composite layup, it depends on the direction of the load. In compression, the matrix carries the load because the yield strength in compression for the fibers is nonexistent. However, the matrix is typically a type of plastic and can be considered a ductile material. When loaded in tension, the fibers carry the load and can be brittle. Buy that is not always the case. Concrete is the opposite; the matrix is brittle, and the fibers or the rebar are ductile.

Like bone, most natural materials can have different properties depending on many variables, like age. I like to say kids are made of bubble gum and magic; they bounce right back. Understating the material’s properties is paramount for any design but especially for machine design. Typically, several different types of materials are acted upon by the principal stresses of the system. Depending on the principal stress’s material type and direction, there will be a need to determine the appropriate failure theory.

For example, is the material ductile or brittle? What direction is the loading? Is it in shear, bending, tension, or compression? And will it change in the future due to loading, yielding, stress, or environmental exposure?

What Is A Ductile Material?

A material exhibits ductility if a body made of it can change its original shape through a permanent displacement. Permanent displacement occurs when a body experiences a load or a combination of loads that forces it to relieve the applied stress by yielding to the stress and permanently changing its shape through displacement. The material has yielded—or is also known as plastic deformation. Most common steels, aluminum, and plastics are ductile under standard conditions. However, there all depended on temperature.

What Is A Brittle Material?

A material that fractures without significant yielding is considered brittle. More often, brittle materials are stronger in compression than in tension. Whether or not a material is brittle is dependent on the characteristic of the material. The characteristic of the material determines how to interpret the results.

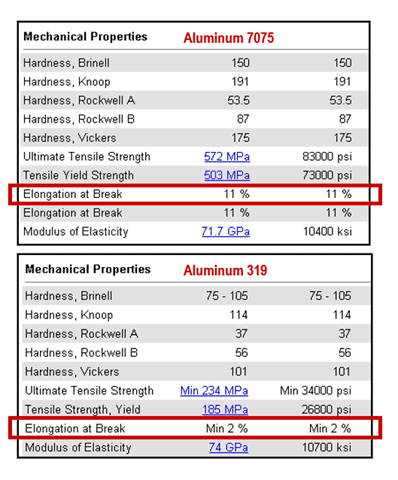

One of the characteristics that you must understand is to identify if the material is brittle or ductile. When reviewing the material properties, is the percent of elongation at or below 5%? In the past, we called this the 5% rule. The 5% rule used to be just a rule of thumb. But in a later post, we will show how the 5% rule is used to determine the correct static failure theories theory.

Another indication is if the ultimate tensile strength is less than the ultimate compression strength. Additionally, there is no yield strength reported for the material from time to time, which is a good indication that the material is brittle. Some common brittle materials are cast iron, ceramic, and diamonds.

Assumptions Blind And Theory Guides

Above we pointed out some common material that is typically brittle or ductile. However, understanding that it is a huge mistake to assume that the material is one way or another without reviewing and understanding that material species and the environment it operates.

For example, the above image shows two different aluminum types we identified earlier as ductile material. However, not all aluminum species are ductile; for example, Aluminum 319 is a brittle material and needs to be analyzed as a brittle material using the Static Theory of Failure for brittle material.

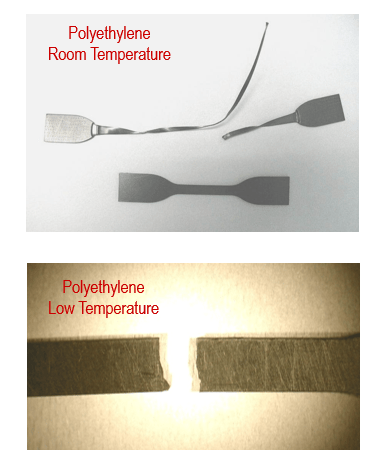

There are also the environmental effects on which the material operates. For example, below are two cases of polyethylene. When polyethylene is at room temperature, it is a ductile material. However, many materials at some lower temperatures become brittle.