You see the smoke roll in through the open door, and you get up to investigate. The acrid smell of smoke attacks your throat and lungs as your eyes burn. Your lungs lock shut, knowing your next inhale will be your last. You have seconds left before you die, you must find the exit, but you can no longer open your eyes to the pain.

According to the NFPA, smoke incapacitates so quickly that people are overcome and can’t make it to an otherwise accessible exit.

You are the engineer. You understand building ventilation and NFPA 90, the Smoke Control System standard, and how critical the design is to save lives. You have done it before—this is not your first rodeo. You have performed smoke ventilation calculations for years, decades even. However, …

However, how well did those systems work? Or did they only work in theory—with no direct way to honestly know? Could we have done better? How could we have designed the system better — ensuring that lives are saved?

Have you considered using CFD simulation?

Our World Is Changing

Smoke Control Systems are not just another engineered system that is slapped onto a building. It is part of a comprehensive approach to Fire & Life Safety. There are always new regulations on the horizon. They seem to get more challenging each time they’re updated.

For example, we must show proof to regulators for multiple fire-location scenarios. Last-minute design changes are the norm, e.g., when the architect moves a few walls (or expands the atrium) like it is no big deal. Then it is your last-minute job to show their impact on the Smoke Control Systems. Ouch!

Your Smoke Control System and Design Documents must keep up with the changes. And they must be defensible to regulators.

New Tools Mean New Abilities Leading to Better Outcomes

Today Building Information Modeling (BIM) is the norm. Performing Computational Fluid Dynamics (CFD) Modeling for Building Ventilation and Smoke Control is not as difficult as it used to be.

Using CFD early in the design process is the fastest and cheapest way to prove your design works and meets code.

The downstream benefits are enormous. With the early and often method, today’s cloud-connected CFD allows for faster solutions and the ability to solve multiple scenarios (running in parallel) on large on-demand servers. For Smoke Control applications, this results in the ability to solve numerous fire scenarios simultaneously, as easily as running your HVAC heating and cooling ventilation loads.

Why Do I Need CFD?

Any engineer who expects more stringent future regulations, last-minute design changes, and troubleshooting of existing designs should consider the benefits of CFD:

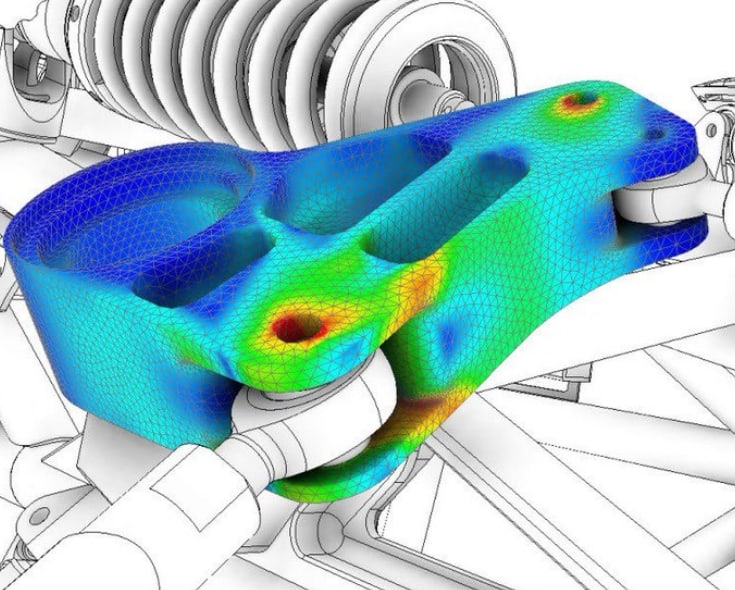

- CFD simulations Models examine building scenarios in much greater detail.

- Accounts for the impact of irregular shapes and unusual air movements that cannot be addressed by either zone models or algebraic equations.

- Provides a level of refinement that exceeds what any of us can model by hand or derived from equations alone.

- Let’s you look your client in the eye and say, “This system not only meets code, but we’ve also modeled it to show you exactly how it works!”

When Should I Use CFD?

Start using CFD Simulation for fire and smoke control as soon as you start placing air outlets and inlets! Engineers are always guessing where to put supply diffusers and how much air from each one to get the best distribution. And there is that argument that returns grill placement is not that critical.

Why keep guessing when you now have the tool to know? Those who wait until the system has been designed face the following obstacles:

- CAD Model time increases—with the time-consuming cleanup of the model—to remove unnecessary detail.

- Design options decrease—the design gets “locked-in”—reducing your ability to identify the optimal locations for supply, return, and exhaust diffusers and grills—some of the most significant things you can do to ensure your design works.

- Other obstacles mount up—obstacles you will see when using CFD early in the design cycle.

How Do I Use CFD?

Pure Prime Solutions (PPS) has you covered. We have experts in CFD that provide the following:

- Expert on-demand: Providing clients with CFD experts to assist with training, mentoring, and support. Typically, we set up templates and settings for applications like Smoke Control and others.

- Completed -For-You: Giving you the engineering expertise you can trust. And we are available to perform your CFD Simulations for a quick turnaround.

- Performed-With-You: Furnishing staff augmentation services that perform engineering and simulations for you and then use the engineering and/or simulation project as examples to transfer the necessary knowledge to your staff.

What Comes Next?

If you are an HVAC Engineer (or Technical Professional) responsible for Life Safety in building design. And you…

- Own that responsibility that the public has entrusted you.

- Understand the criticality of Smoke Ventilation.

- See new regulations on the horizon.

- Want to be ready for last-minute design changes.

- Need to see how the air is moving.

Then, now is the time to investigate the speed—and iterative capabilities—of CFD Modeling of Fire and Smoke—with PPS… do not delay.

A Question for You…

How are you addressing Ventilation & Smoke Control today?

What do you see on the “regulatory horizon”?

How will you be ready? LEAVE A REPLY. Thanks.

Your input will shape future blog posts. We cannot do it without you! Please tell us what you think. Thanks for your help.